LELOX Cutting delivers precision laser and waterjet cutting services with an unwavering commitment to quality. We utilize cutting-edge technology and meticulous processes to ensure your project is completed to the highest standards.

At LELOX Cutting, we transform your designs into reality. Our precise cutting techniques, combined with our expertise in various materials, bring your vision to life with accuracy and efficiency.

LELOX Cutting utilizes the latest laser and waterjet cutting technology to provide unparalleled precision and speed. Experience the difference that advanced technology makes in achieving exceptional results for your project.

With LELOX Cutting, the possibilities are endless.

Our precise cutting services cater to a wide range of industries and applications, empowering you to create intricate designs and complex components with ease.

LELOX Cutting is your partner throughout the entire fabrication process.

From initial concept to final creation, our comprehensive cutting services and expert team support your project at every stage.

Whether it’s mild steel, stainless steel, aluminium, brass, copper, we’ve got the capability to cut through it all with unmatched precision and efficiency.

About us

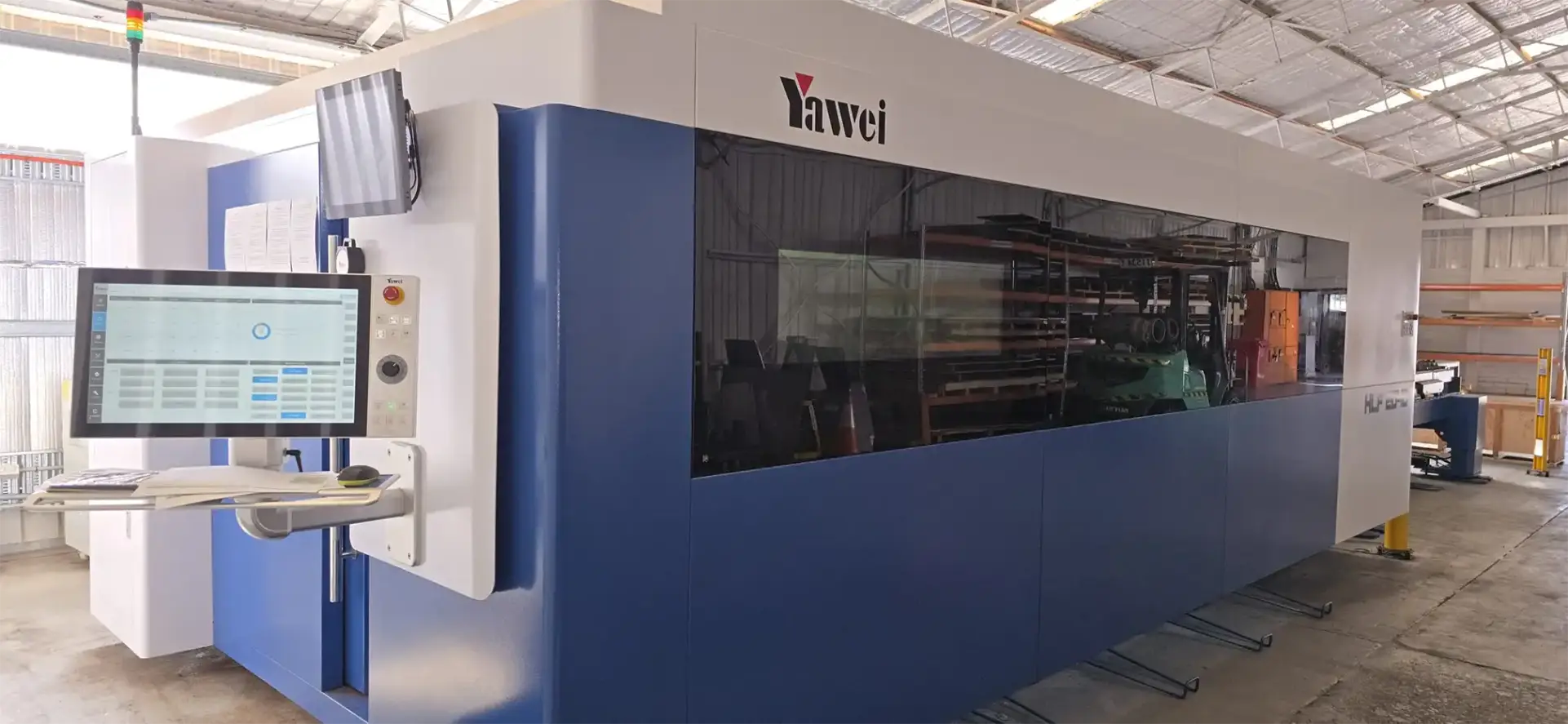

At LELOX Cutting Services, we pride ourselves on precision cutting, with state-of-the-art technology and an unwavering commitment to quality. Our world class 12kW CNC laser cutting machine is engineered to handle a number of materials—mild steel, stainless steel, aluminium, brass, and copper—with unmatched accuracy and efficiency.

From small jobs to large-scale projects, our cutting solutions deliver excellence that sets the industry standard.

Complementing our laser capabilities, our FLOW waterjet cutting machine offers unparalleled versatility, cutting virtually any material up to 75mm thick. From metals like stainless steel and aluminium to specialised materials such as carbon fibres, composites materials, fibreglass, wood, plastic, and rubber, our waterjet system ensures clean, precise cuts tailored to your requirements. Whatever the material, LELOX delivers results that meet the highest standards of quality and accuracy.

Lelox Quality Commitments

Material Assurance and Test Certificates

At LELOX Cutting, our expert team is equipped with state-of-the-art technology to handle all your cutting needs.

Our FLOW waterjet cutting machine can cut through virtually any material up to 75mm thick with unparalleled precision. Whether you’re working with metals like mild steel, stainless steel, and aluminum, or need to cut gasket materials such as fiber and fiberglass, wood, plastic, or rubber, we’ve got you covered. LELOX delivers clean, precise cuts every time, ensuring your project meets the highest standards of quality and accuracy.

BEST PRICE, FAST DELIVERY.

We can cut up to

40mm mild steel

Image Accordion Content Goes Here! Click edit button to change this text.

50mm stainless steel

Image Accordion Content Goes Here! Click edit button to change this text.

50mm aluminium

Image Accordion Content Goes Here! Click edit button to change this text.

20mm brass

Image Accordion Content Goes Here! Click edit button to change this text.

16mm copper

Accordion content goes here!

Lelox Waterjet Cutting Services:

At LELOX, exceptional customer service is at the heart of everything we do. From initial consultation to final delivery, we are committed to communication, precision cutting, correct product handling, rigorous quality control, and on-time delivery every time. We understand the importance of your project timelines and strive to be the cutting partner you can rely on.

FAQ

At LELOX cutting services, the quickest and easiest way to get a quote is to send your drawing in DXF format. We understand that not everyone has access to this format. In this case, send through any drawing (PDF, Picture, etc) and our technical team can draw this on CAD software. An additional charge may occur for this service.

Our beds for laser and waterjet cutters are 4 metres x 2 metres. We can cut any piece that can fit on the bed.

Waterjet cutting uses water with abrasive to cut through any material. The waterjet operates at around 60,000psi to cut through any material.

Laser cutting uses a high powered and highly focused laser to cut through metals.

This depends on the material and the machinery used. Our Laser machine can cut up to; 40mm mild steel, 50mm stainless steel, 50mm aluminium, 20mm brass, 16mm copper.

Our waterjet machine can cut up to 75mm thick, depending on the material.

Why choose Lelox cutting services

At LELOX, we pride ourselves on delivering cutting solutions that put our customers first, prompt quotes, fast turnaround times, and speedy delivery.

Whether it’s high-volume projects or intricate custom work, trust LELOX Cutting Services to exceed expectations and bring your vision to life.

Flexible Delivery

Part Number Etching

Extensive Material Range

Competitive Pricing

Traceability

Technical Assistance

Fast Quotes

Australian Owned

Jen Sharp

Gina Kee

Lelox has a great team of guys so professional, and the process of ordering has been made very easy...

Allan Thrift

Ben & his team at Lelox cutting are fantastic. After being stuck for a last minute gift idea, I approached them with a one off order...

Mel Hurdis

James Pike

Nan Li